Our Energy Programs

Steam and condensate programs

Steam Trap Management & steam/condensate

Starting a Steam Trap Maintenance Program might seem like a large undertaking for many facilities; however, the benefits far outweigh any costs and effort involved. Implementing a steam system maintenance program can save time, reduce costs, and improve operating efficiency and product.

With today’s energy costs and demand for production reliability, it is extremely important to have a pro-active steam trap station management program included with the overall steam system management program. A steam trap station failure rate must be below 3% annually. To achieve a reliable steam trap station system, root cause analysis has to be part of the program. We can no longer accept failures of more than 3% with steam trap station components. Today, plant operation mandates a steam trap station to be reliable for at least 6 years or longer.

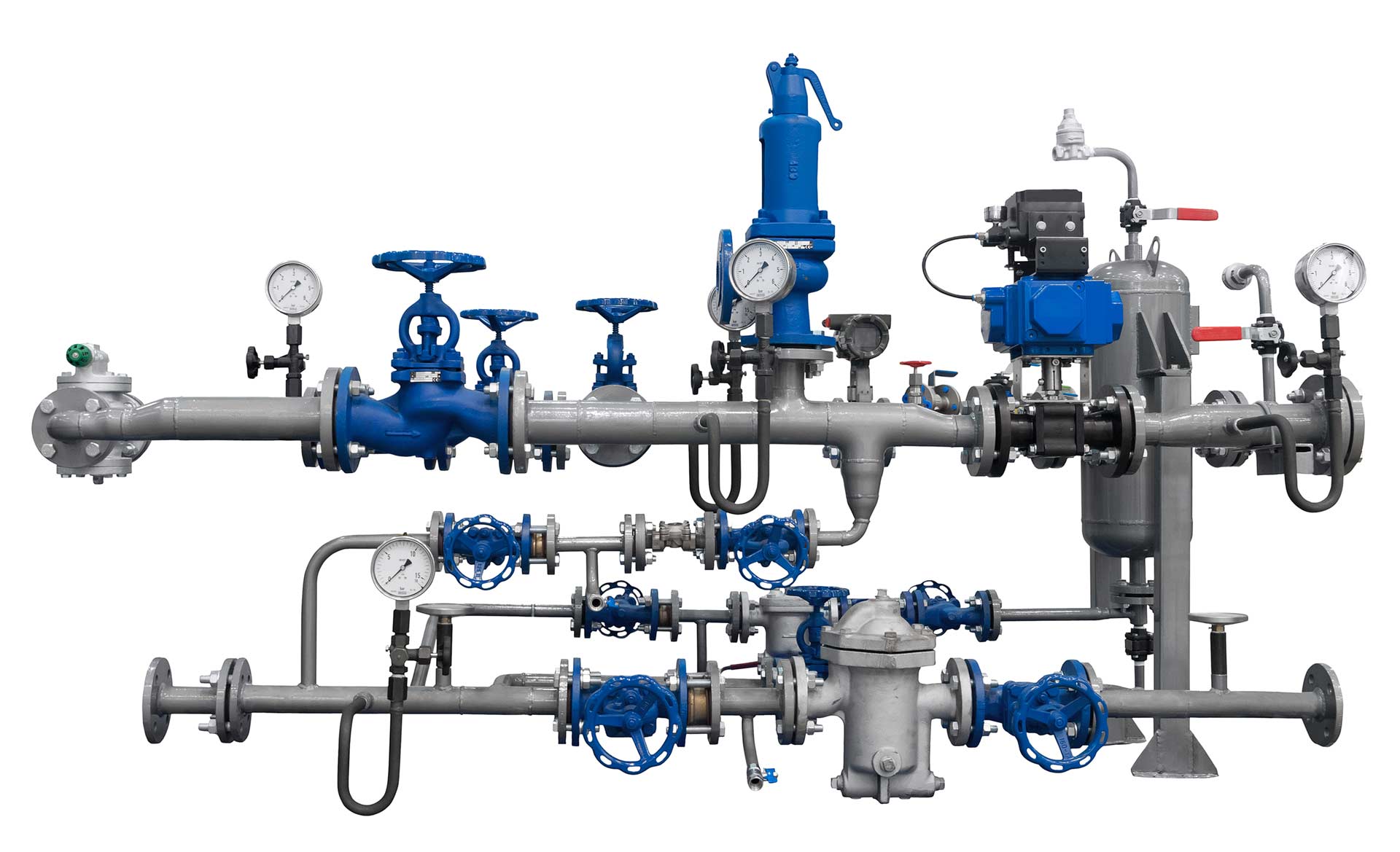

Why steam trap station management instead of steam trap management? Steam traps are only one component in a proper steam trap station arrangement. Just reviewing the steam trap instead of the entire steam trap station can lead to an unsuccessful steam trap station management program. Poor steam trap station management is a major cause of energy dollar losses and significantly increases emissions in today’s steam system operation. A successful steam trap station management program can identify defective steam valves, steam traps, strainer failures, and blowdown valve failures. Additionally, with this documentation and knowledge, the amount of energy and emission impacts for each steam valve or steam trap failure can be calculated.

A steam trap station program will accomplish the following:

- Reduce energy losses

- Increase system reliability

- Keep failure rates below 3% annually

- Decrease combustion emissions

- Decrease production downtime

- Improve steam quality

How do we start with a survey and how does it work?

-

Registration and inventarisation of steam traps

Carefully register the location of each steam trap, maybe with the help of existing data. We note all information, like brand, type, usage, etc. During the inventarisation, we already do part of the analysis. We look for specific problems, like steam- and water shock, wrong dimensions of condensate systems and badly designed pipe configurations, wrong type of steam trap, etc.. The first inspection is usually the most difficult and time consuming one. Steam traps are preferably indicated on a floor plan.

-

Creating a database

The registered information is kept in a database. A correct build-up of the measuring database is necessary for the execution of reliable measurements.

-

Inspection of steam traps

Next to being inspected as to being operational, also an inspection is needed of the leaks of flange connections, setup and the right application for this type of steam trap, mounting error, external steam leaks, opened bypass taps, etc.

Because of the many variables in a steam system, for example back pressure, a temperature measurement alone is not the most reliable indicator. A visual inspection of steam traps with atmospheric drainage is also not reliable because visible steam plumes can be created because of revaporised condensate, caused by the pressure difference over the steam trap. The most reliable measurement is the combined temperature/ultrasound measurement.

-

Reporting

The after-inspection report is the instrument for a proactive and cost-conscious policy. With a good report, the person responsible can make an action plan, based on facts.

If you require Steam and Condensate Program or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.

Ultrasound is an essential part of a proactive reliability program as it can reduce or eliminate wasted compressed air through leak detection and repair.

A compressed air system can be responsible for as much as 30% of a factory’s overall energy consumption. Wasting part of this energy through leaking compressed air pipework is simply throwing away money. Analysis of your compressed air system is an excellent way to start the optimisation of your plant or manufacturing facility.

Ultrasound Compressed air or other gasses like nitrogen Leak Detection Surveys cover a wide range of leaks: pressure or vacuum and any gas. Sound dependent, ultrasound instruments detect the turbulent flow produced as the fluid (liquid or gas) moves from the high-pressure side to the low-pressure side of a leak. Ultrasound leak inspection is especially beneficial in areas where there is a saturation of gases or where a wide variety of gases, pressurized vessels and vacuum processes exist. For this reason, ultrasound leak detection is used in many facilities for safety, environmental, energy or quality assurance programs.

We provide Leak Detection Surveys to identify the compressed air or gas leaks at your facility. The survey includes detailed reporting (even a calculation per leak what we lose in euros) to help you repair each leak, which will save thousands of euro’s each year in energy consumption.

An annual air leak survey followed by fixing the biggest 25%

of all leaks will save your 80% of the wasted energy

For Trusted Compressed Air Leak Surveys, Call Us Today on +32 471 74 34 56

With many years of experience in performing and completing compressed air leak surveys at a range of commercial and industrial properties, Maintenance Holding BV is here for you. If you are seeking leak detection services in your area and wish to instruct a reputable company, we are here to help. For more information or for further details about the many other services we offer to our customers, contact us today.

If you require Compressed Air and Gas Leak Programs or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.

We mainly specialize in measuring and inspecting valves, safety valves and all kinds of valves going to the flare. Leaking valves cost money and also put pressure on the flare pipes which can be a hazard.

Volatile emissions can cause a problem in some production facilities. In many cases, leaking equipment can lead to various accidents, harmful emissions of gases or chemicals. Neglecting to detect these volatile emissions comes at a cost... When they get into the air we breathe, several hazards can arise. While some volatile emissions only cause unpleasant odours, others can pose a serious threat to the safety and environment of both plant personnel and people living near the facility.

Steps to setting up a monitoring programme

-

Step 1 - Understand the process and monitoring objectives

Before deciding on a monitoring technique, it is important to think about what actually goes on within your company’s processes. Consider the following questions for each process:

- Is the emission a single stream or a complex mixture?

- Is the process operating on a batch or continuous basis?

- Is the sampling port in a designated and intrinsically safe area? If not, then equipment that potentially produces sparks or flames (e.g. FIDs) must not be used.

- Could particulate emissions cause problems?

- Do emissions have a high moisture content? Moisture interferes with most sampling techniques, e.g. by saturating sorbent tubes and preventing uptake, and causing problems with laboratory equipment.

- Are the emissions at a high temperature? High stack temperatures will restrict the use of concentration and flow-measurement techniques, so it is wise to check the manufacturer’s specification before using equipment. In addition, high temperature emissions will affect sampling arrangements, due to the health and safety risks involved.

-

Step 2 - Identify appropriate techniques and equipment

Your plant may have many different VOC streams, each of which could be monitored using a

variety of techniques. When selecting monitoring techniques and equipment it is important to

consider a number of factors, including:

• Type of data required and monitoring objectives, e.g. specific compounds or total carbon;

• Regularity of monitoring required, for example:

- Continuous, i.e. monitoring over an extended period to profile the emissions;

- Routine, i.e. regular monitoring for leaks as part of a maintenance programme;

- Periodic, e.g. monitoring to comply with legislative requirements, carried out, say, every six months;

• Safety considerations;

• Particular operating restrictions, e.g. process temperature, and humidity;

• Accuracy and repeatability required;

• Capital and operating costs.

-

Step 3 - Decide between monitoring in-house and contracting out

The next step is to decide whether to:

- Contract out monitoring to a specialist company;

- Hire the equipment and perform the monitoring in-house;

- Purchase the equipment and carry out the monitoring in-house.

-

Step 4 - Cost the options

Estimating how much the monitoring programme will cost is an important step. Make sure you include the cost of any in-house resources, such as staff time.

When obtaining quotations from monitoring contractors, specify:

- What is to be monitored, how regularly and for how long;

- The specific information required and how it is to be reported;

-

Step 5 - Select the most appropriate approach

Once you have all the cost information, you will be in a position to choose the most suitable

route for your monitoring programme.

-

Step 6 - Implement a monitoring programme

When implementing monitoring you should:

- Assign responsibility for the programme to a member of staff;

- Set out what is to be measured, how and when, and draw up a proper monitoring programme including a timetable and key actions/responsibilities;

- Establish some means of recording the results (e.g. on a spreadsheet or database).

When monitoring is contracted out, make sure that your company and the contractor fully agree on the programme.

Regardless of the form of measurement used, it is important that all measurements are as accurate and representative as possible. You can achieve this by:

- Studying manufacturer or method notes carefully before making any measurements.

- Choosing duct access and measurement points carefully, bearing in mind that they should be located on the longest and straightest runs of ducting.

- Conducting monitoring over a period of several days of normal, steady production, and avoiding start-up and shutdown periods.

- Taking sufficient samples to provide statistically meaningful results. For example, a few sets of four or more readings (of adequate length) are usually sufficient to give a sensible overall mean. You should take into account process type and changes as these will influence the concentration gases and how this level changes with time.

If you require Flare Valve surveys or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.

If you require a Monitoring and Reducing VOC Emissions Survey or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.

BTW: BE0890163951

Business Booster powered by Proximus