Industry 4.0 describes an important technological advancement driving automation and data exchange in the manufacturing environment to provide smart production with its efficiency improvements, while setting the requirements and needs for necessary and essential tools to specifically enable the change. Predictive Maintenance can be one of this tools.

Machine Health Check – Condition Monitoring

Condition Monitoring is not only about Rotating Equipment

Health checks are vital to the well-functioning of your equipment.

Health Check Services typically include machine profiling (information gathering), data base set up and conducting an initial health check assessment on accessible plant items.

Should you wish for specific Condition Monitoring services to be deployed at your facility, then Maintenance Holding is able to provide the provision of a Reliability Engineer to suit your needs.

The condition monitoring services provided under the ’Health Check’ can include, but are not restricted to

- Vibration analysis

- Oil analysis

- Ultrasound analysis

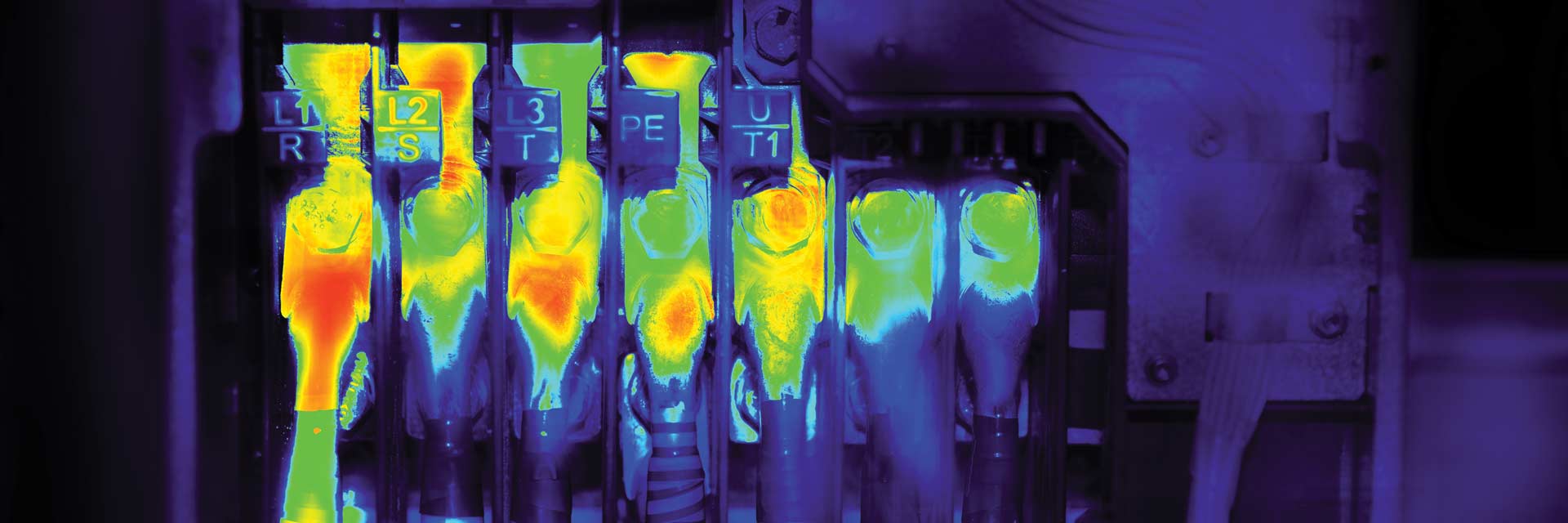

- Electrical Thermography

- Mechanical Thermography

Maintenance Holding BV can provide a CBM Engineer for a number of days per month to conduct these Condition Monitoring Services. Maintenance Holding BV provides detailed analysis and an online reporting system from these services within two working days on completion of each survey.

Condition Monitoring

How to use Condition Monitoring as a Proactive Equipment Reliability Improvement Strategy?

Through the use of a CM spectrum, faults or problems are easily discovered.

Condition Monitoring, when used to drive reliability improvement, offers diagnostics, information and data for Root Cause Analysis and equipment redesign, along with verification of defect or design correction. Condition monitoring applied proactively is a context embracing world class reliability maintenance concepts.

A Definition of Condition Monitoring (CM): The process of systematic data collection and evaluation to identify changes in performance or condition of a system, or its components, such that remedial action may be planned in a cost-effective manner to maintain reliability.

While the basic definition of Condition Monitoring may have general application across many industries, the objectives for Condition Based Maintenance (CBM) may vary greatly.

Why would one do Condition Monitoring?

The most commonly used techniques of condition monitoring are

• Vibration Measurement and Analysis

• Oil COndition and Wear Debris Analysis

• Thermography

• NDT, especially thickness testing

• Visual inspections

• Performance trending, e.g. flow rate measurement

If you require Condition Monitoring or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.

Visual inspections

A visual inspection is an inspection of an asset made using only the naked eye.

This kind of inspection does not necessarily require any special equipment, but it does require special training so that the inspector knows what to look for as they visually review the asset.

Visual inspections have traditionally taken place with an inspector walking around or inside of an asset like a boiler, visually reviewing every single part of it.

But new Remote Visual Inspection (RVI) tools have been allowing inspectors to collect visual data without having to be physically present, changing the approach as to how they conduct visual inspections. In fact, some RVI tools are so good that inspectors can rely almost entirely on the visual data they collect for the purposes of their inspection.

What Is the Goal of a Visual Inspection?

Visual inspections are one of the oldest and most trusted ways to evaluate the condition of an asset as part of the overall maintenance process.

The goal of a visual inspection is to find anything that might be wrong with the asset which could require maintenance.

For example, if an inspector is conducting a visual inspection of the inside of an industrial boiler, they might be looking for:

- Cracks or buckling in the welds that hold the boiler together

- Corrosion on the sides of the boiler

- Leaks or other issues with the integrity of the boiler’s walls or floor

- Issues with any of the supporting equipment that helps make the boiler run

The primary goal of finding these issues is to fix them before they get worse.

Visual Inspection Report Form

A visual inspection report form is completed by quality assurance inspectors to document pass/fail decisions on visually inspected products based on set defect criteria. This customizable visual inspection report form can be used as a mobile-ready checklist app to easily access reference images and identify visual defects. Quality inspectors should use this checklist to effectively:

- Indicate product ID and location

- Capture photo evidence of products and/or defects

- Determine pass/fail decisions based on a reference image

- Identify visual defects based on defect criteria

- Complete the visual inspection with a digital signature

Maintenance Holding BV can help you to set up, perform or train people for these visual inspections, in both electrical and mechanical inspections.

If you require a Visual Inspection or if you would like to request a check-up on your system, use our simple online contact form to find out more from our expert, reliable and experienced team.